Question: I installed new pressure treated deck boards about 5 years ago and now I have to replace them. The pressure treated boards are in good shape except for the ends where I am getting rotting and splitting. I purchased pressure treated lumber because I was told it would last for 40 years. Why is this happening?

Answer: There are two possible reasons why the ends of the pressure treated lumber are rotting and splitting:

- Pressure treated lumber has high concentrations of copper in the treatment chemicals. The use of certain metal fasteners, such as steel and poorly galvanized metals into the pressure treated lumber creates a galvanic reaction. The fasteners begin to rust and this in turn damages the deck lumber. It is best to use stainless steel fasteners when dealing with pressure treated lumber.

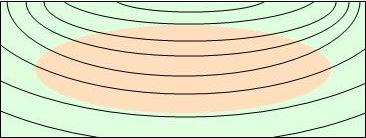

- The second possibility has to do with the treatment of the lumber. To create pressure treated lumber, the lumber is impregnated with chemicals under pressure. However, in many cases the chemicals do not go all the way through the lumber. If you have cut the deck boards to fit the cut ends of the lumber you may notice that the outer edges of the boards are green in color, but the center of the board is a light yellow or the basic color of untreated lumber, as shown in Figure 1.

If you replace the pressure treated lumber with the new ACQ pressure treated lumber the problem of galvanic corrosion is even worse. There are fasteners which are specifically made for ACQ pressure treated lumber, but I would still opt for using stainless steel!

Figure 1 - End grain of pressure treated lumber

When you cut pressure treated lumber it is best to coat the end grains with a wood preservative prior to installation.

------------------------

- Egress Windows & Decks

- Deck Board Spacing

- Replacing Deck Boards

- ACQ Pressure Treated Lumber

- Cleaning a Redwood Deck

- Composite Deck Material – Recall!

- Deck Preservation

- Constructing Deck Foundations

- Using Cantilevers In Decks