Common questions and answers for those considering the purchase and installation of a hardwood floor - Cont'd:

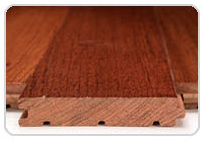

Figure 1 - Tongue and groove hardwood flooring

When should I use an engineered hardwood flooring versus a solid hardwood flooring?

The advantage to engineered hardwood flooring is its stability. It does not bow, expand, shrink or twist when confronted with moisture. Engineered hardwood can be installed using the traditional nail down method, glue, or stapled. In some cases engineered hardwood can be laid as a floating floor where it sits on the surface without any nails or glue holding it down to the sub-floor. Engineered hardwood is the perfect product for rooms that are below grade and full bathrooms.

What is better, a pre-finished or unfinished hardwood flooring?

In today's market most hardwood flooring is sold pre-finished. A pre-finished hardwood floor can be installed in one day. Pre-finished hardwood flooring, is very durable, much more durable than self finished product. Manufactures utilize numerous coats of a polyurethane and/or aluminum oxide which are cured under ultra violet light. The benefits of a pre-finished product are somewhat obvious, no dust from sanding, no odors from stains and finishes and time for installation.

The advantage of a unfinished hardwood is the ability to mix and match stains.

Is hardwood flooring suitable for high traffic areas?

The new high durability polyurethane finishes make hardwood flooring an excellent choice for high traffic areas. Hardwood flooring can now be conveniently used in kitchens, foyers and family rooms. The new polyurethane finishes, are rugged, they are wear resistant and are impervious to most stains. They do not require waxing, hence there is no need to continuously strip the hardwood floor, apply wax and buff. The biggest enemies to a hardwood floor finish are grime and dirt. Grime and dirt act like sandpaper when walked on. They scratch the surface of the floor. To avoid this problem use mats in doorways and runners in halls leading from the doorways. Sweep and vacuum high traffic areas often.

Why are there square-edge and eased-edge boards and planks?

A square-edged board or plank has square edges. The side edge and top edge are at 90 degrees to one another. An eased edge board or plank has the junction of the edge and the top of the board slightly shaved at an angle. This easing is generally known as beveled or micro-beveled edge. The advantage of an eased edge is that it will mask any slight imperfections in board, plank or sub-floor heights. Although you cannot see these slight imperfections, you can actually feel them if you walk on a hardwood floor with bare feet.

What installation method should I use?

The method of installation of your hardwood flooring is dependent upon 2 things:

- The type and style of the hardwood flooring that you have chosen.

- The material that makes up the sub-floor.

Some engineered hardwood flooring can be installed without fasteners or adhesive. If you are remodeling a kitchen that has vinyl or ceramic tile as the current flooring, you may wish to use an engineered hardwood flooring that can lay on top of these surfaces, thus avoiding the problems and mess associated with their removal. If your sub-floor is concrete, then you would have to use either an adhesive or floating floor.

It may be noted that it is easier to install solid hardwood flooring with a nail or staple boot rather than using an adhesive. Adhesives do not have the ability to draw boards together during the installation process.

What do I need to know if I want to use hardwood flooring in conjunction with in-floor radiant heating systems?

If you are considering the use of either hydronic or electric in-floor radiant heating systems then the best product choice is an engineered hardwood floor manufactured in planks or strips. Engineered hardwood flooring, because of its laminated construction, is not affected by changes in temperature and humidity in the same manner as solid hardwoods are. Choose an engineered hardwood flooring that can be installed without the use of nails, staples or adhesive.

The maximum temperature, of the radiant heat system, measured on the sub-floor should not exceed 80 degrees Fahrenheit. Check with the manufacturer of the hardwood flooring for specific information with respect to radiant heating.

Oak, Ash and Merbau are good choices for in-floor electric radiant or hydronic systems. It is best to avoid the use of Maple and/or Pecan for in-floor radiant heat systems.

How should I maintain my hardwood flooring?

New hardwood flooring, finished with a polyurethane, should never be waxed, as wax traps sand, dirt and other fine particles and they will scratch the floor. A damp mop should not be used on any hardwood flooring as water and hardwood are not good companions. All manufacturers include detailed instructions on the care and maintenance of their products and these instructions should be followed. A broom and vacuum are the only tools that are required.