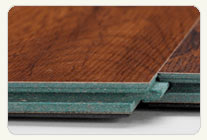

The first point that must be made is that Laminate Flooring, as shown in Figure 1, and Hardwood Flooring only have one thing in common – they are both flooring products. Laminate is as dissimilar to hardwood as ceramic tile is to cork.

Figure 1 - Laminate Flooring

Laminate flooring is now sold with a ceramic tile appearance, as shown in Figure 2, that does not make it ceramic tile!

Figure 2 - Laminate flooring with a ceramic appearance

The fact that it is not hardwood flooring or ceramic flooring, does not make it an unacceptable flooring product it only makes it a different flooring product.

Laminate flooring was first introduced as Pergo (a trademark), and it was immediately accepted as a new, relatively inexpensive, and easy to maintain flooring product. However, there was a great deal of confusion about where the product could and couldn’t be used, its longevity, and overall limitations.

With the acceptance of Pergo, innovations on the successful flooring soon appeared in the market. The new product, often referred to as the “glue-less installation system” created more questions and confusion then its predecessor, Pergo did when it first entered the market. The glue-less installation system is sold and marketed under a variety of nomenclature - snap together, click together and interlocking, depending on the manufacturer.

A flooring material that doesn’t require glue was no less than a brilliant concept. It is the home handyman’s dream, come true.

You simple cut the flooring pieces to length, join the pieces together and you have an instantaneous floor that you can walk on and replace the furniture on, immediately after completion. No toxic glue smell, no sanding, no grouting, no sealing. It provides the same satisfaction and attributes for adults as Lego does for children (or for us older individuals – mini bricks).

Although every manufacturer has coined a phrase to describe their locking mechanism, there are really only two different methods. Chose the method along with the pattern and durability and you have made the decision on which product to purchase. Although there are other differences including the total thickness of the laminate material and the coatings used to protect it from damage.

Snap Together:

Utilizing a tongue and groove assembly methodology, the snap together floor is lined up horizontally and then using a mallet, it is tapped together to create a bond to the previous piece. It is the easiest floor to assemble, but it can only be assembled once and it cannot be taken apart to replace sections.

Snap together floors usually have a lower overall quality than you will find in a click together floor.

Click Together:

Although click together floors use a tongue and groove, they have been modified to create a lock when they are inserted into each other, as shown in Figure 3. The tongue, on the long side of the piece of flooring is inserted into the groove at an angle and then lowered to a flat plain. Minimal tapping at the end joints locks all the pieces together.

Figure 3 - Click together laminate flooring

The flooring can be taken apart and put back together again, however, it is not easy to do this without damaging the edges and corners of the laminate. This provides the advantage of being able to replace damaged sections.

Although the method of interlocking sections of flooring together is important, the core material is what creates the quality of the laminate flooring. Without a high quality, solid core the locking system will fail, break or be compromised over time. Softer cores are much more prone to damage by liquids than solid cores are.