Faucets can and do make a lot of difference to the look of your sink and your kitchen in general. You may opt for retro look or stylish modern styles and choose from a wide range of finishes such as chrome-plated.

Figure 1 - Sink faucet with sprayer

When choosing your kitchen faucet, besides the overall appearance of the faucet there are some other items to take into consideration.

- Kitchen faucet construction:

- Kitchen faucet valve construction:

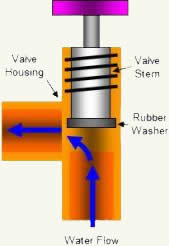

- Compression valves (Figure 3):

- The first is that over time the rubber wears and water will leak through the assembly even when the washer is closed.

- The second problem is that minerals such as calcium which are in the water will begin to form on the seat of the valve (the seat is the part of the valve where the washer is compressed to stop water flow). These minerals will not allow the washer to seat properly and water will drip through to the spout.

- Cartridge valves

A faucet is constructed by creating a faucet body that holds the valves and spout assembly and a finishing material plated or placed over it. The least expensive faucets have a faucet body made of plastic while a quality faucet will have a faucet body made of solid cast and machined brass, as shown in Figure 2.

Figure 2 - Brass valve body

Note: Brass plated faucet bodies will not last as long as solid brass bodies.

The valve portion of the faucet stops or sends the water supply to the spout. There are 4 different styles of valves.

Figure 3 - Open compression valve allowing water to flow

By far the most common of all faucet valves, the compression valve works as the name implies. In its simplest form, a rubber washer is mounted at the end of a threaded screw, as the screw is tightened it pushes the washer tight against the incoming water line, stopping the water from flowing. As the screw is loosened water can flow through the assembly.

There are hundreds of different thread sizes, lengths and diameters.

There are two basic problems with compression valves:

Figure 4 - Cartridge valve

Cartridge valves can be made of a few different materials, the ones with the longest life are made of brass. A cartridge valves basic design uses a cylindrical piece of metal and an O-ring to control the flow of the water, as shown in Figure 4.

Over time, as normal wear occurs, the O-ring may need replacement, however it is an easy and relatively inexpensive repair.