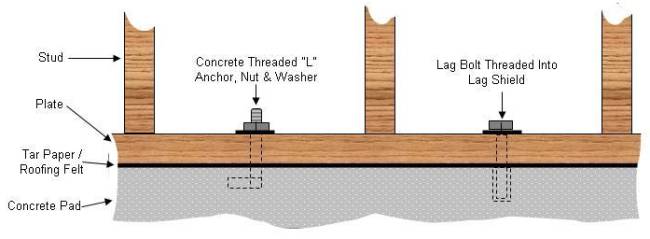

Figure 1 - Garage constructed on concrete pad

The type of fastener used to hold the building or structure to the pad is determined by whether the pad is in place or is to be poured.

Concrete Pad To Be Poured (Figure 3):

Figure 2 - L

concrete foundation anchor bolt

When pouring the concrete pad insert L

concrete foundation bolts, as shown in Figure 2, into the concrete in the correct position, the center of the bottom plate of the stud wall.& Before inserting the concrete anchor into the concrete apply a grease or Vaseline on the threads to prevent wet concrete from adhering to the bolt.

Make sure that the bolts are vertical. If they are not vertical, you will have problems mounting the bottom plate over them.

The bolt should protrude 3″ to 3 1/2″ from the finished surface of the concrete pad. Use a large washer and nut to fasten the bottom plate. The hole drilled in the bottom plate should be 1/8″ bigger than the bolt. This allows for expansion and contraction of both the concrete pad and the bottom wood plate..

Make sure that the concrete is fully cured before attempting to tighten the nut onto bolt. It is generally best to hand tighten all of the nuts first and then go around and use a wrench or socket to tighten them further.

Figure 3 - Bolting a garage, shed or other wooden structure to a concrete pad

Concrete Pad Already In Place (Figure 3):

Figure 4 - Lag shield

Figure 5 - Lag bolt/screw

If the pad is in place the best way to fasten the bottom plate of the wall to the concrete pad is in the use of a lag shield, as shown in Figure 4, lag bolt, as shown in Figure 5 (sometimes referred to as a lag screw) and a large washer.

The lag bolt should be 4″ long and a 1/2″ thick. The lag shield should be 2″ long. Using a carbide tipped concrete bit, drill an appropriate sized hole (for a 1/2″ lag bolt the shield usually requires a 5/8″ hole).

Drill a 5/8″ hole in the plate (this allows for some expansion and contraction) then thread the lag bolt through the bottom plate and into the lag shield. Use a large washer on the head of the lag bolt to avoid drawing the lag bolt through the lumber.

The bolts should be placed a maximum of 6 feet apart - 4 feet is better. There should be a bolt within 2 feet of every corner. Cadmium plated or galvanized bolts will work, but for a longer life consider using stainless steel.

Additional information on using pressure treated lumber.

Additional information on using concrete fasteners and anchors.

Additional information on concrete pads.

Use a layer of tar paper, roofing felt or sill plate gasket to keep the bottom plate from having direct contact with the concrete pad in order to prevent moisture from being drawn up through the pad and into the lumber. This will save the wood from rotting.

Additional information on sill plate installation.

Trick: When placing the concrete anchors, either the L

bolts or lag shields, mark a length of 2 X 4 with the position of the studs, lay it beside the concrete pad and insert the concrete bolts between

marks. By doing this you will avoid having the concrete bolt end up under a stud position.